Effective Support Equipments Designed for Optimum Toughness

The design of efficient support systems is essential in making certain optimal stamina and reliability throughout numerous applications, specifically in civil and marine design. As we check out the different kinds of support systems and the materials that underpin their effectiveness, it becomes noticeable that the future of anchoring technology might hold even greater advancements.

Relevance of Support Systems

Anchor systems play an essential role in numerous applications, from marine building to overseas drilling and even in the security of structures on land. In marine atmospheres, supports are important for mooring vessels, stopping drift due to wind, currents, or waves.

In addition to marine applications, anchor systems are crucial in civil engineering, especially in the building of retaining walls, bridges, and buildings in geologically tough locations. These systems help distribute tons successfully, neutralizing forces such as soil stress and seismic task. The importance of support systems expands to the renewable resource market, where they safeguard wind turbines and offshore systems, adding to the stability and effectiveness of energy generation.

Eventually, the effectiveness of an anchor system is essential to the safety, durability, and performance of numerous frameworks, making their design and application a crucial element in design and construction practices across several markets.

Ingenious Products in Anchor Style

Modern improvements in materials science have significantly changed anchor design, boosting efficiency and toughness. The consolidation of composite materials and high-strength alloys has actually caused anchors that can hold up against severe environmental problems while maintaining architectural stability. These innovative products not just supply remarkable tensile strength however also lower weight, enhancing convenience of setup and handling.

One noteworthy growth is using carbon fiber reinforced polymers (CFRP), which give outstanding deterioration resistance and high strength-to-weight ratios. This permits the design of anchors that are both light-weight and extremely durable, making them suitable for marine applications where direct exposure to saltwater can cause product deterioration.

In addition, advancements in finishes-- such as advanced epoxy and galvanization-- additional shield metal anchors from rust, expanding their life span. These coverings can be tailored to fulfill specific environmental difficulties, making certain that supports do accurately also in harsh conditions.

Additionally, the combination of wise products, which can adjust to transforming lots and environmental factors, is paving the way for future anchor styles. These growths highlight a trend towards higher performance and integrity in anchoring remedies, eventually enhancing safety across different applications.

Sorts Of Reliable Support Systems

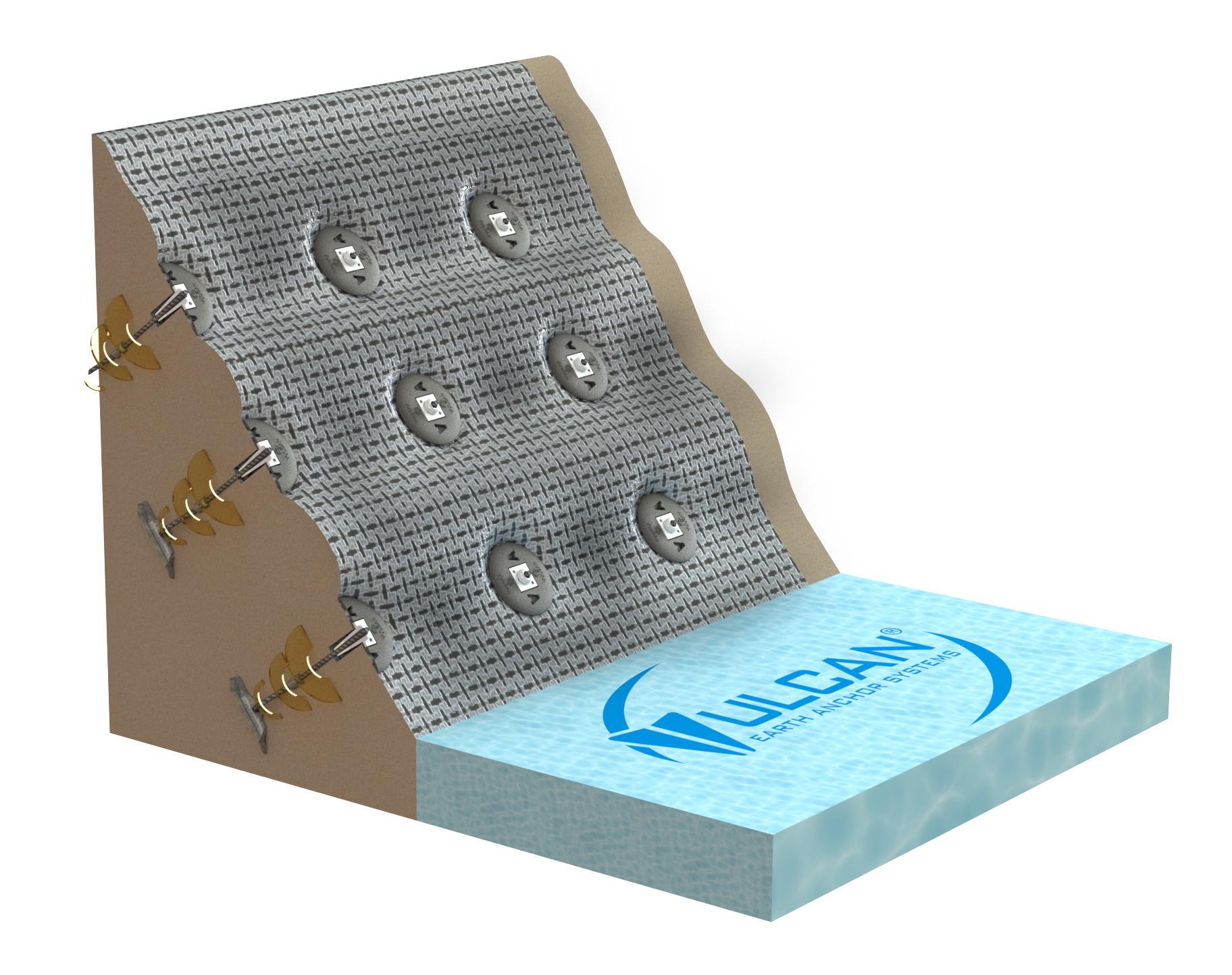

Efficient securing remedies are necessary for guaranteeing stability and safety and security in different applications, from building and construction to aquatic operations. Several kinds of effective anchor systems stand out for their effectiveness and versatility to different atmospheres.

One prominent kind is the screw anchor, which uses a helical design to offer remarkable holding power in soil and soft ground. These supports are specifically helpful in temporary frameworks and can be quickly gotten rid of and recycled.

One more utilized system is the driven pile support, usually employed in hefty and aquatic building and construction projects. These supports are driven deep right into the ground, giving exceptional resistance to side pressures, making them excellent for sustaining huge frameworks.

For aquatic applications, the mooring buoy anchor system is important. This system consists of buoyant devices connected to anchors on the seabed, enabling vessels to continue to be secure while lessening drag from currents and winds.

Lastly, the deadweight support system depends on heavy weights to supply stability and is commonly utilized in overseas setups. Each sort of support system is developed to satisfy details requirements, ensuring the safety and integrity of frameworks and vessels in numerous conditions.

Safety And Security Criteria and Laws

Guaranteeing the security and reliability of anchoring systems involves adherence to rigorous safety and security criteria and policies. These standards are established by various companies, including the American Society for Screening and Materials (ASTM), the International Company for Standardization (ISO), and neighborhood building codes. Compliance with these regulations is essential to guarantee that anchoring systems can stand up to ecological stress and anxieties and loads, reducing the danger of failing.

Evaluating and accreditation procedures are basic parts of safety criteria. Securing systems must go through rigorous evaluations, including tensile stamina tests, fatigue examinations, and ecological effect examinations. These tests help identify the systems' performance under real-world problems, guaranteeing they satisfy or exceed the required safety and security limits.

Additionally, producers visit this website are required to sites supply comprehensive specifications and guidelines for installment and maintenance, which are integral to upholding safety and security requirements. Regular examination and upkeep protocols have to likewise be established to recognize prospective weaknesses gradually.

Future Patterns in Support Innovation

The future of anchor modern technology is poised for significant improvements, driven by the enhancing need for improved safety and efficiency in construction and design applications. Developments are anticipated in materials, layout, and installation strategies, which will boost the strength and longevity of anchor systems.

One arising trend is the assimilation of smart modern technology into anchor systems. Earth Anchor. By including sensors, these systems can keep an eye on stress, tons, and ecological conditions in real-time, enabling proactive upkeep and raised reliability. Furthermore, advancements in composite materials might bring about lighter, yet stronger anchors that can hold up against extreme conditions, decreasing the total weight of structures

Moreover, modular anchor systems are acquiring traction, permitting easier installment and flexibility to different job requirements. Earth Anchor. As the industry welcomes automation, robot setup techniques can better enhance the anchoring process, enhancing performance and accuracy

Conclusion

In conclusion, effective support systems play a vital duty in guaranteeing the security and safety of civil and aquatic engineering jobs. Adherence to safety and security standards and guidelines better highlights the value of reliability in anchor systems.

The style of reliable anchor systems is important in ensuring maximum stamina and integrity across various applications, especially in civil and marine engineering. As we check out the various kinds of support systems and the materials that underpin their effectiveness, it ends up being obvious that the future of securing modern technology may click here for info hold even higher innovations.Ensuring the safety and dependability of anchoring systems includes adherence to rigid safety and security criteria and regulations.In conclusion, efficient anchor systems play a vital function in making sure the security and safety and security of civil and aquatic design jobs. Adherence to security requirements and guidelines additionally highlights the value of integrity in support systems.